| Condition Desc. | used |

| Manufacturer | Held Hydraulics |

| Volts | 460 |

| Model | 8500 |

| Serial # | custom |

| Length | 48 |

| Width | 60 |

| Height | 75 |

| Weight | 3000 |

| Phase | 3 |

This is a truck freight item which will require us to get a shipping quote. You can complete the checkout and provide payment information but you will not be charged until you agree to the freight charges. We will contact you with the freight quote. If you are providing your own shipping contact us.

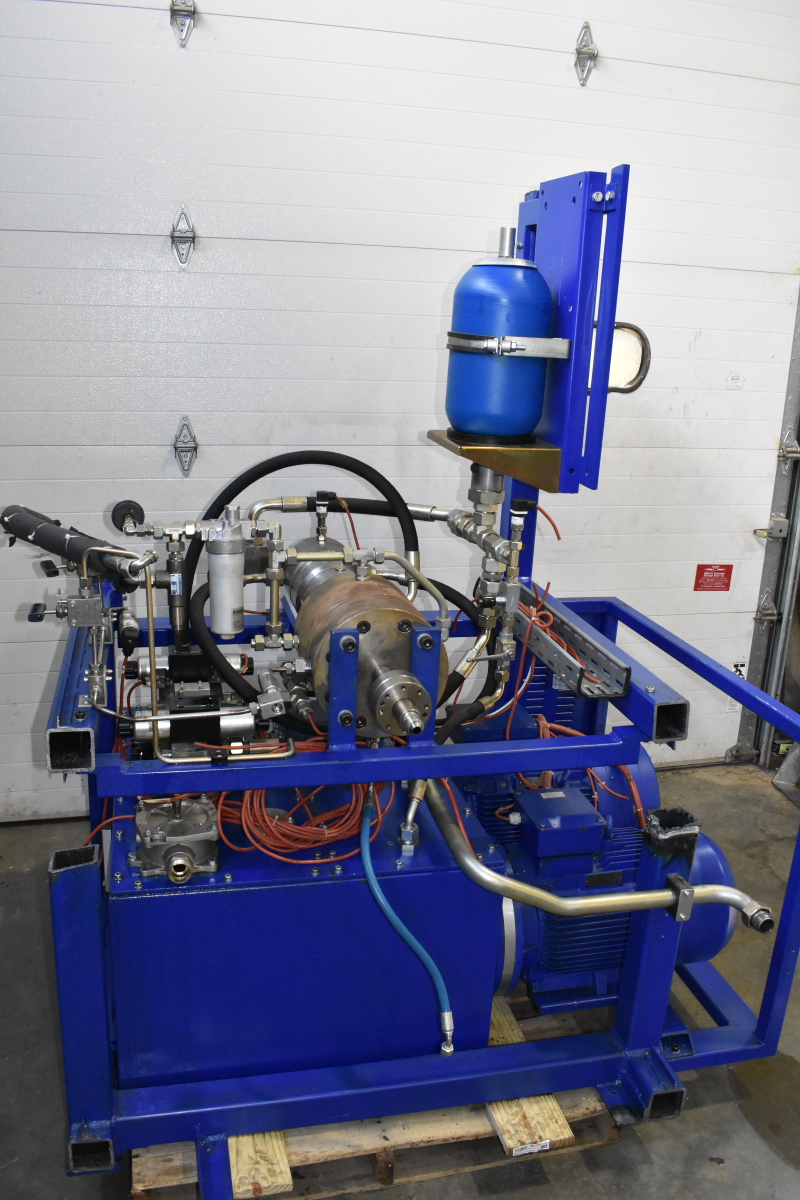

Mfg: Held Hydraulics

Mdl: 8500

Quantity: 1

Inventory #: 9166

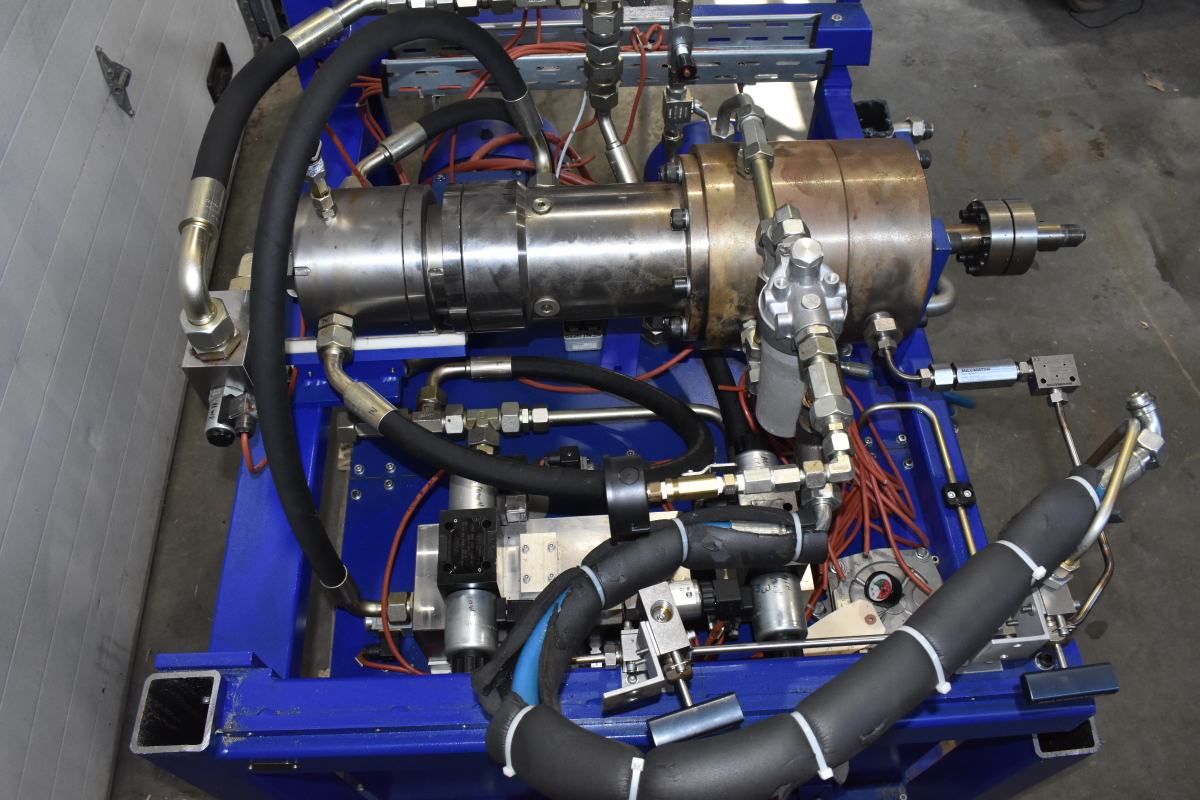

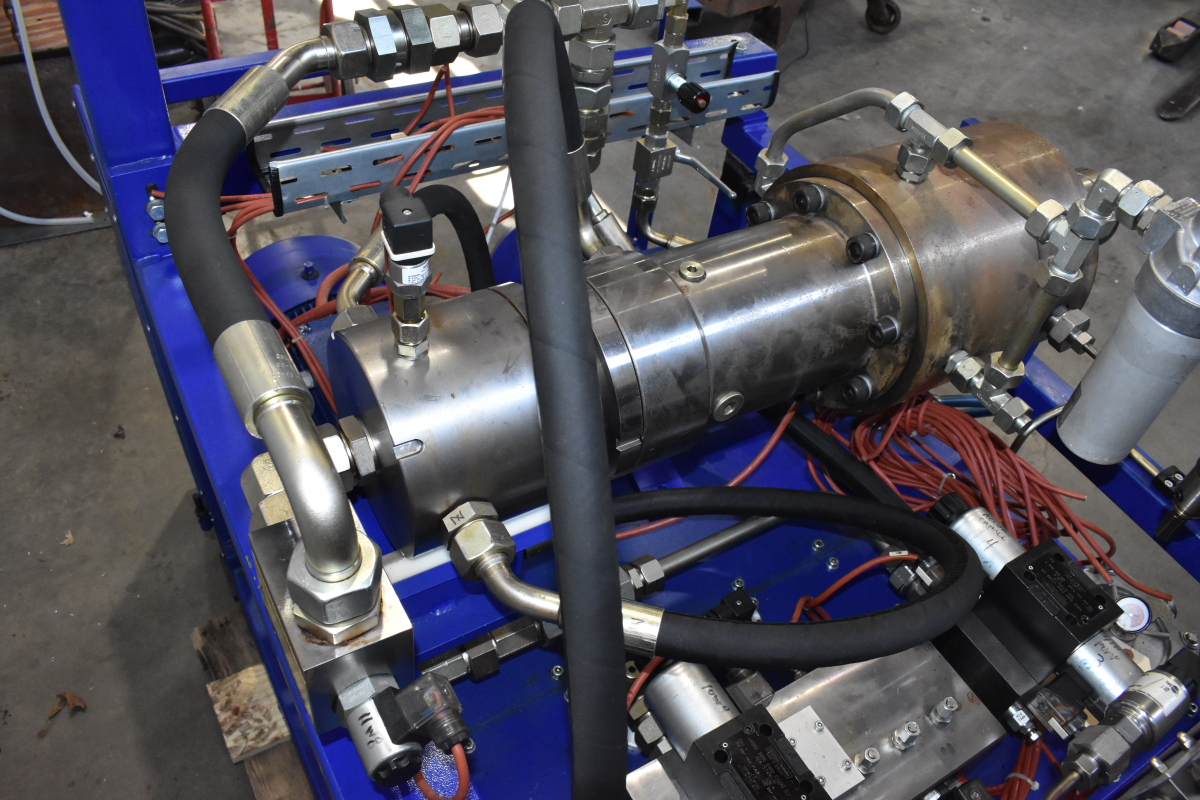

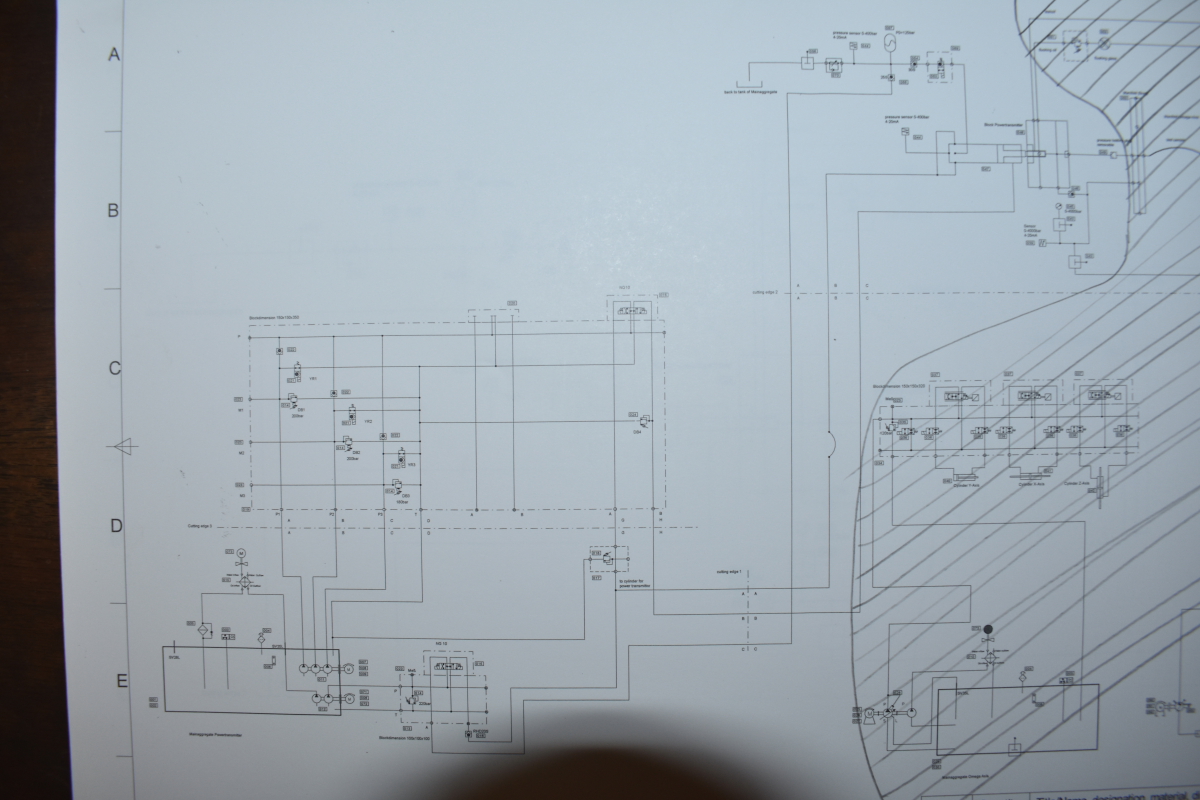

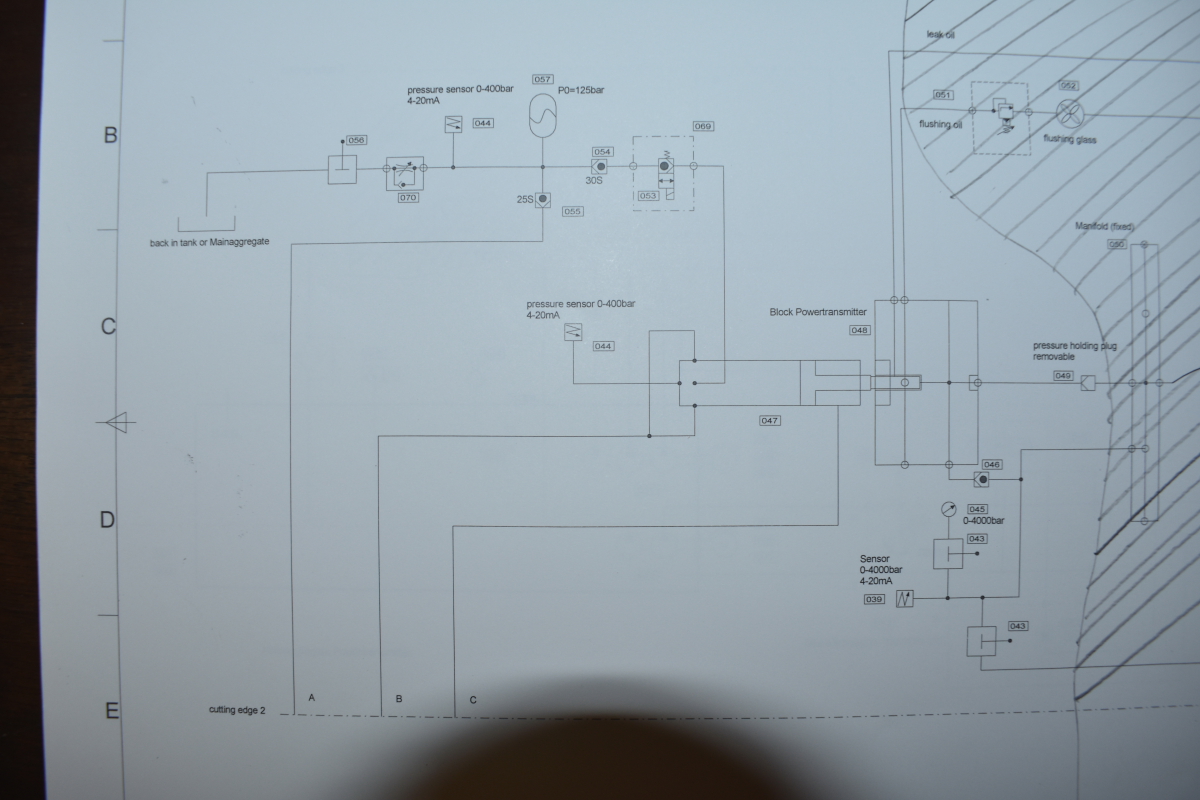

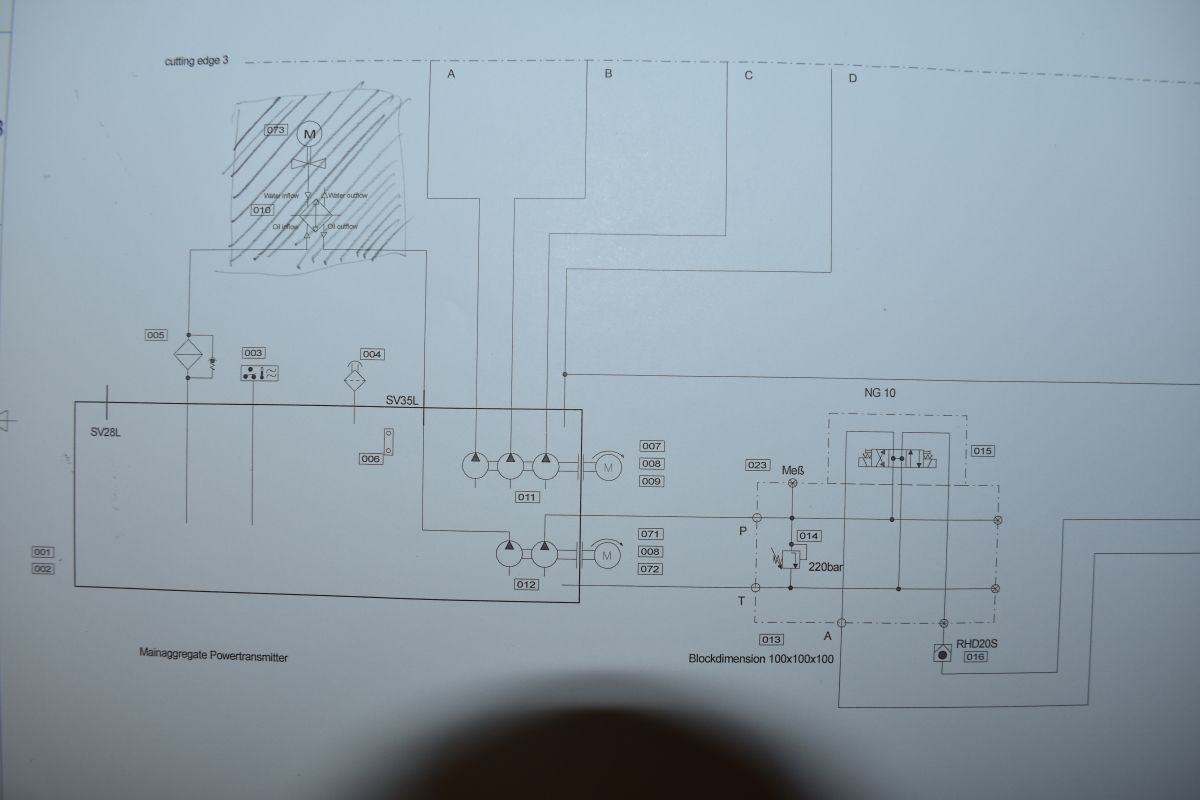

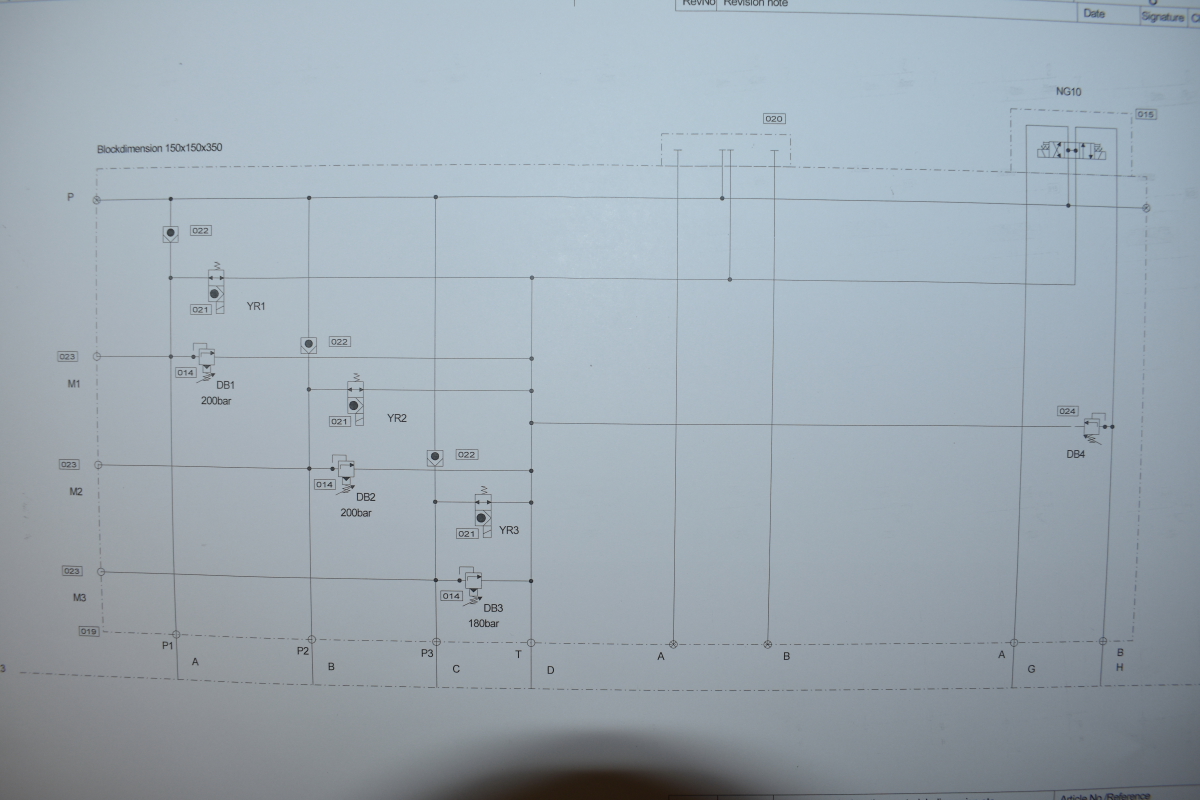

This is a custom built hydraulic intensifier for providing 8500 PSI hydraulic pressure to a process or test stand. Unit was removed from a hydraulic hose impulse test stand and it mostly self contained with intensifier, two hydraulic supplies, tanks, valves and accumulator. The original diagrams are shown in the pictures and higher resolution copy's are available. There is no control system included so the valves would need to be connected to a control system such as a PLC or relay bank to provide the proper sequence of actuation to operate this machine. When this system was originally installed in the original machine it could have also had a 28mm piston in the intensifier which would have lowered the available volume but also increased the operating pressure to 44,000 PSI. (44K Psi piston not included)

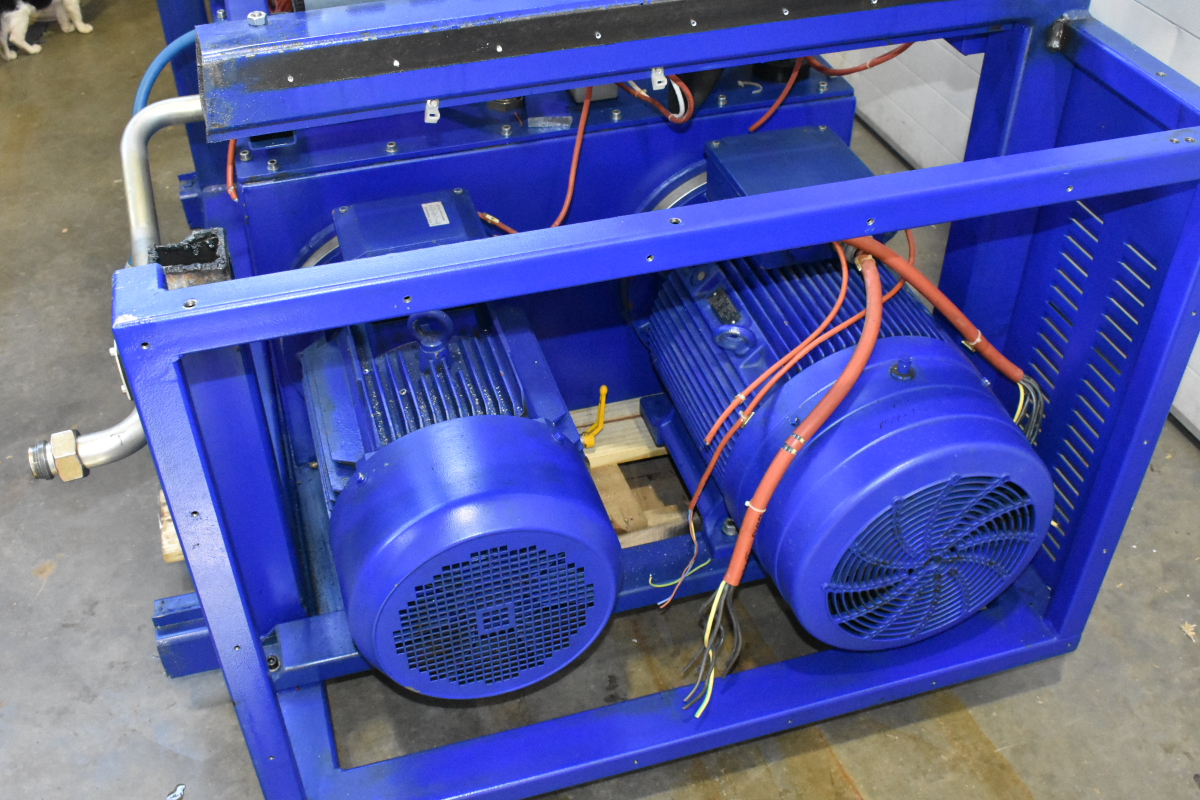

The intensifier is basically a dual acting hydraulic cylinder connected to a precision piston which creates the higher pressures. The intensifier reciprocates back and forth due to alternating hydraulic signals from the solenoid valves. The solenoid block is feed by two separate hydraulic pumps. One pump has three stacked pumps and the other has two. A bladder accumulator is also plumbed into the system.

This unit was built by a German company and was cut from the rest of a hydraulic hose testing machine that had fundamental positioning system design flaws. This impulse intensifier section of the machine worked well and outlasted the positioning system of the original machine. Since the machine was built in Europe it uses mainly ISO fittings and components.