| Condition Desc. | used |

| Manufacturer | Carver |

| Volts | 460 |

| Model | G30H-411 Monarch |

| Amperes | 22 |

| Serial # | 3710 |

| Length | 33 |

| Width | 43 |

| Height | 79 |

| Weight | 1800 |

| Phase | 3 |

This is a truck freight item which will require us to get a shipping quote. You can complete the checkout and provide payment information but you will not be charged until you agree to the freight charges. We will contact you with the freight quote. If you are providing your own shipping contact us.

Mfg: Carver

Mdl: G30H-411 Monarch

Quantity: 1

Inventory #: 9442

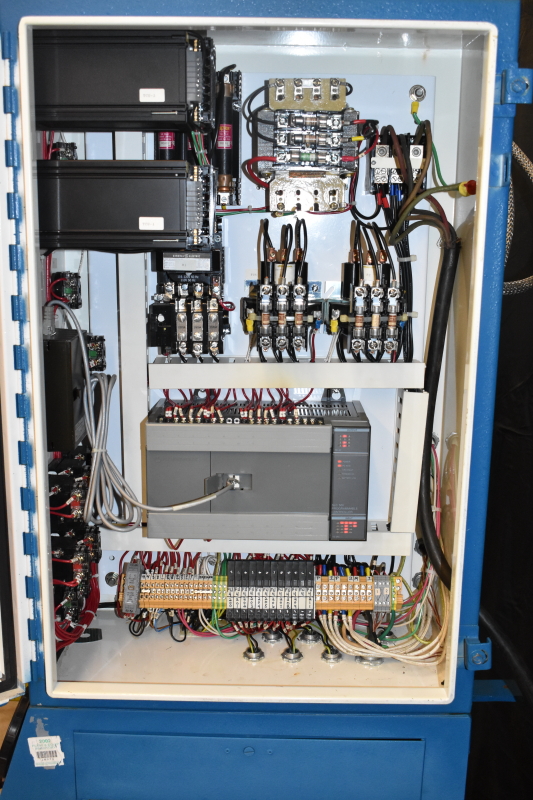

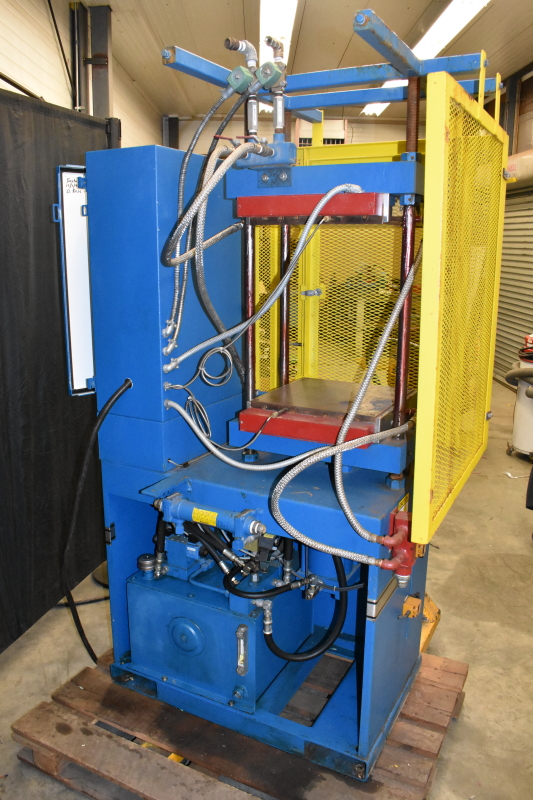

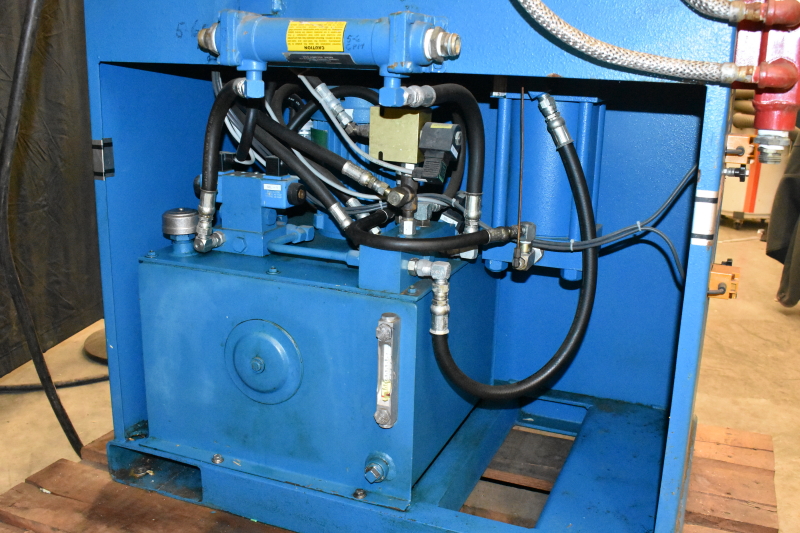

This is a 30 ton Carver / Wabash dual pressure platen hydraulic press. This press features a programmable controller that controls low and high pressure circuits that allows recipes to have dual pressure settings and times. The platens are electrically heated and controlled with dual digital West 2052 temperature controllers. The platens are cooled with compressed air and water. This press has 19.5-27" of day-light whereas a standard G30H has 6-12". The controller system can work in manual mode where an operator has to hold down both "clamp close" buttons to close and hold the press until the "open" is pressed or it can be operated in "auto" mode that starts a press cycle that is programmed on the user interface. The hydraulic system has two pressure ranges, high and low. Once the pressures are set for each circuit in manual mode the press can be operated in auto mode.

The PLC controls the cycle in auto mode and allows the user to select time segments for low pressure, high pressure, air cooling, water cooling and air purge. The operator selects with the push/pull buttons if they want to use the low, high, water and/or air cooling in the cylce. Then then operator enters the times into the user interface in minutes or seconds for each segment. The cycles are started by pressing both "clamp close" buttons and once the "slow down" proximity switch is activated the PLC starts the first timer segment. After all the segments are completed the press automatically opens.

The press was fully tested and all of the functions work well as can be seen in the test video. Press is in good condition for the age and shows little signs of use.