| Condition Desc. | used |

| Manufacturer | Aqua-Chem |

| Volts | 416-460 |

| Model | TWPS |

| Serial # | 4387 |

| Length | 20 |

| Width | 8 |

| Height | 8 |

| Weight | 9500 |

| Phase | 3 |

This is a truck freight item which will require us to get a shipping quote. You can complete the checkout and provide payment information but you will not be charged until you agree to the freight charges. We will contact you with the freight quote. If you are providing your own shipping contact us.

Mfg: Aqua-Chem

Mdl: TWPS

Quantity: 1

Inventory #: 8836

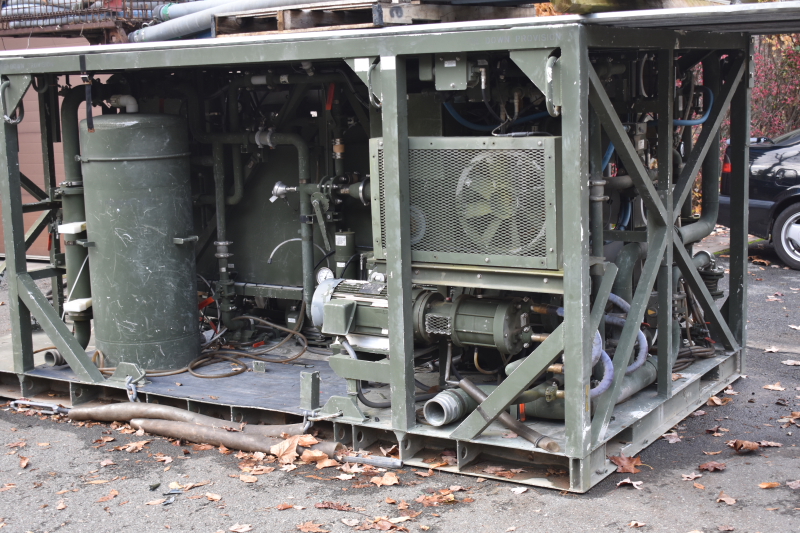

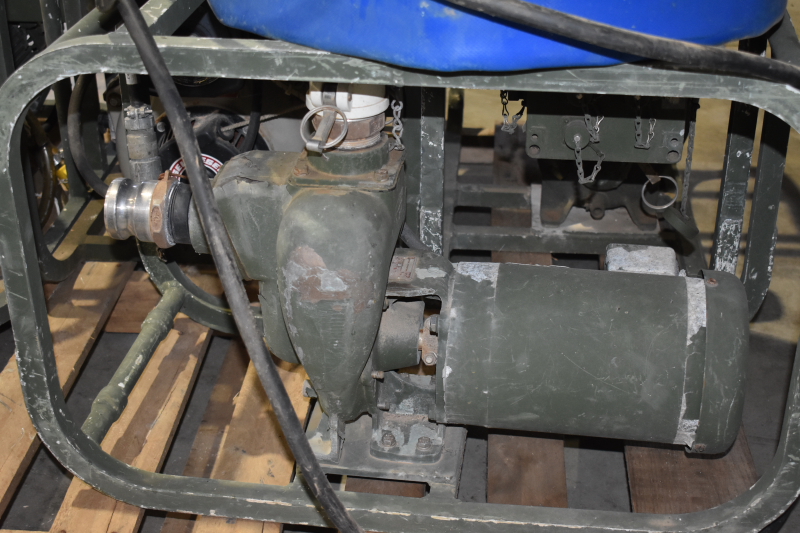

This is a fully self-contained water filtration skid for making potable water from brackish, seawater and contaminated water. Unit uses micro-filters and reverse-osmosis to provide up to 1500 GPH of purified water. This was designed for the military to create drinking water from streams, lakes and the ocean but it obviously could be used by any group or agency needing to make potable water. This skid has many features and accessories so it can be used in different configurations.

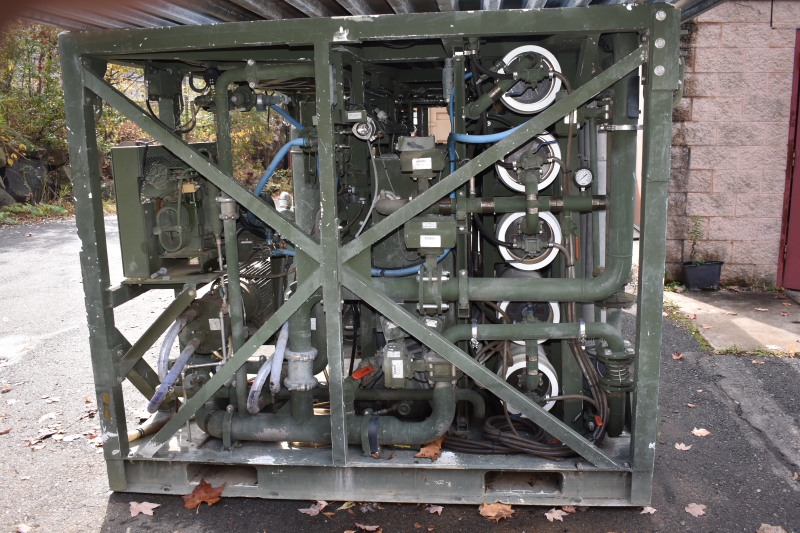

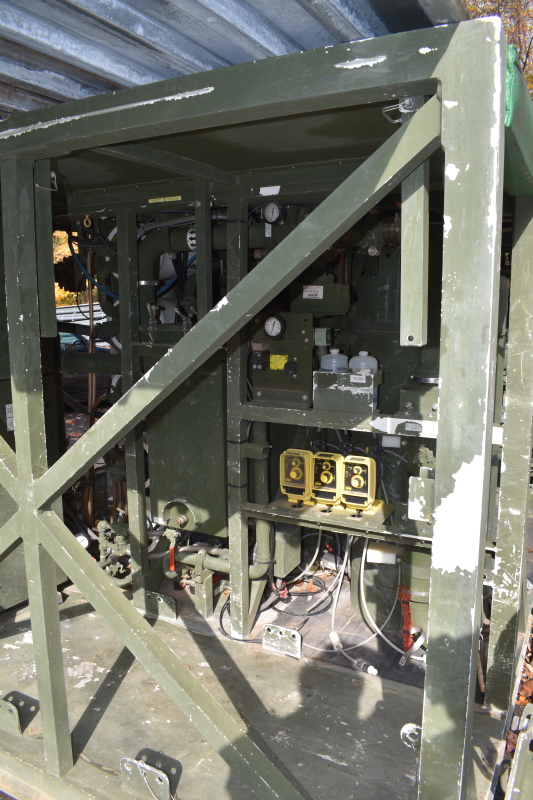

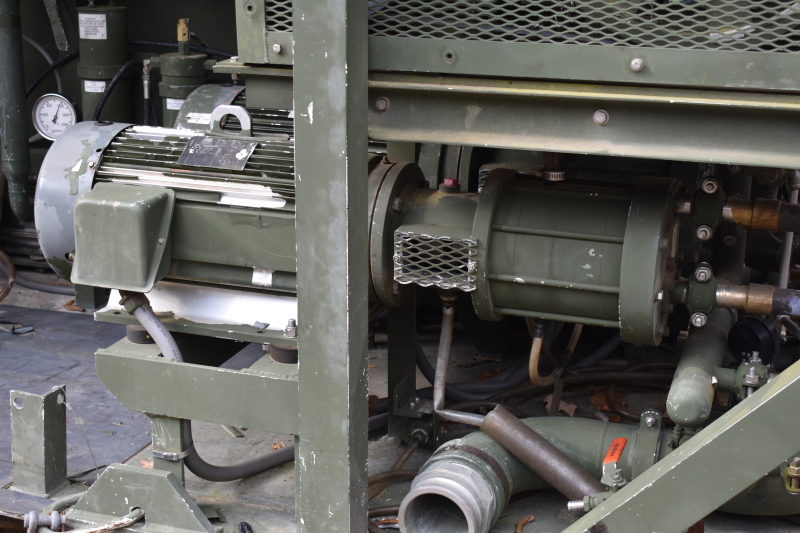

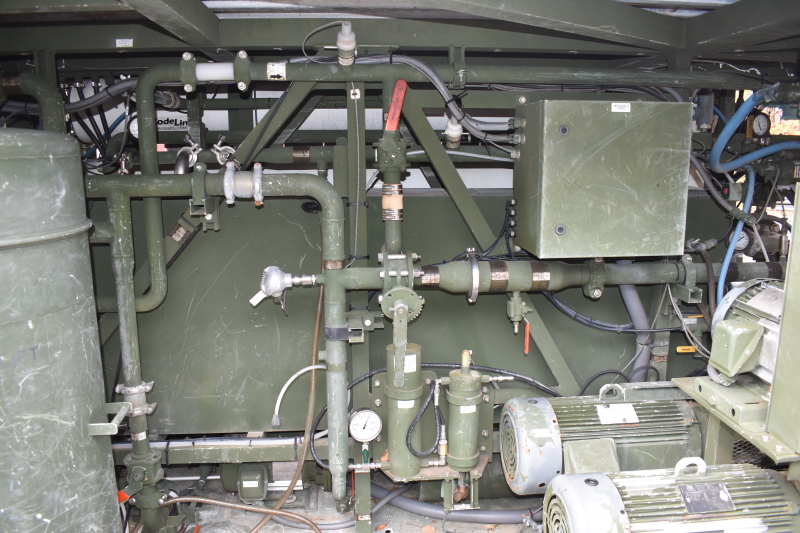

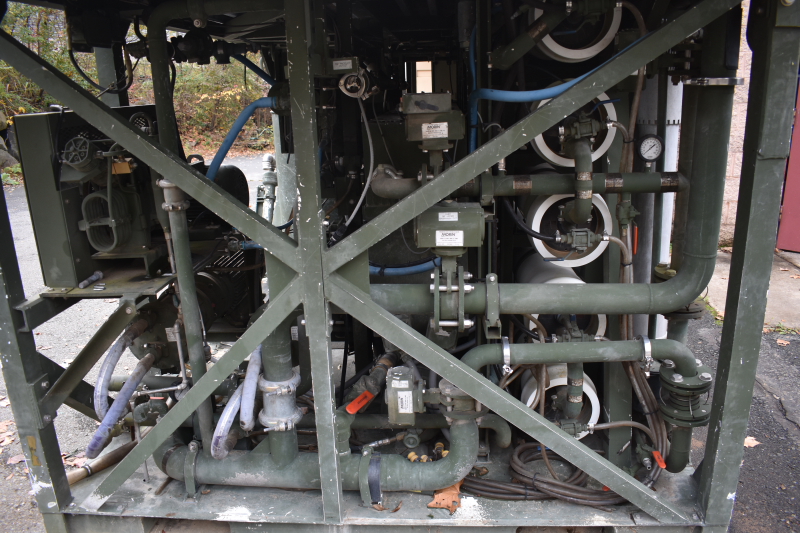

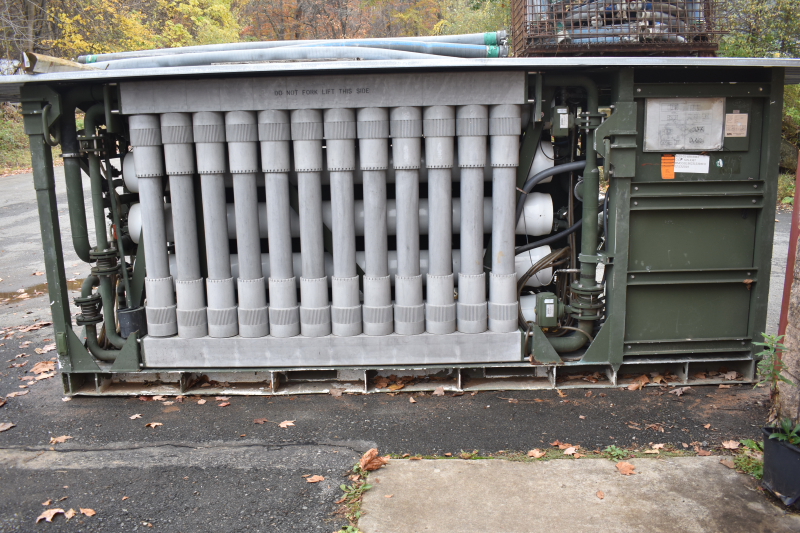

The skid is powered by 460V three phase electric power that needs to come from the grid or a generator. The main components of the system are the MF filters, RO filters, control system, pumps, valves, chemical injection system, high pressure compressor and several ancillary portable pumps, couplers and pipes. Raw water is drawn from the source with the ancillary pumps, pumped through the cyclone separator and then into the skid. The water travels through a strainer and through various valves where it enters the twelve Mirco-Filtration modules. The MF modules remove suspended solids and microorganisms with filter elements that have bundles of hollow pourus fibers. The suspended solids that are accumulated are then removed with automatic backwash cycles.

The MF filtered water becomes the supply for the RO membranes. There is also a RO feed tank that holds a stock of the MF water that is used as RO supply during the time the MF modules are being backwashed. There are two high pressure RO feed pumps that supply the RO membranes with high pressure feed water.

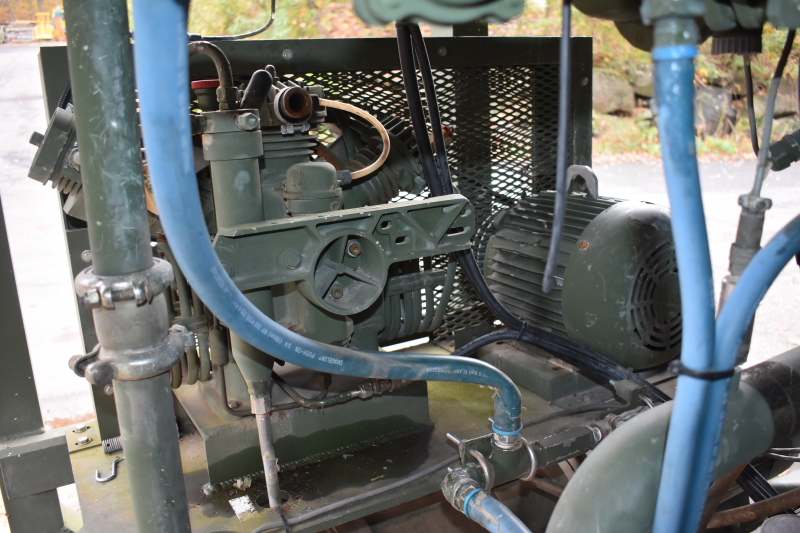

The air compressor system consists of a Bauer three cylinder high pressure compressor that provides high and low pressure air for the various components. Some air is used to blow filtered material loose from the mirco-filter elements during backwash and some air is used to operate many of the pneumatic valve operators.

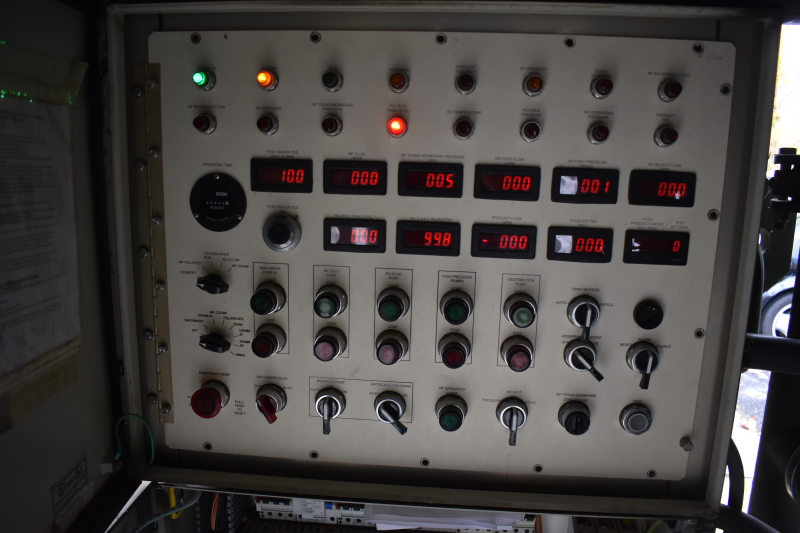

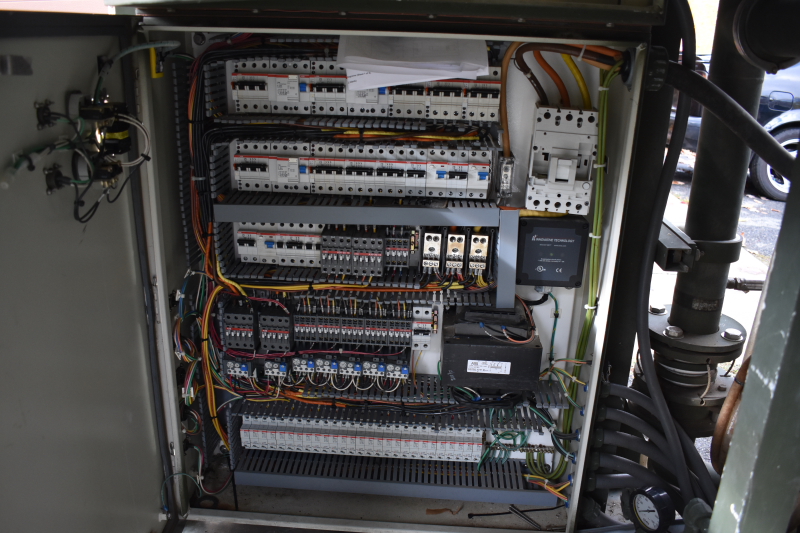

The entire systems is PLC controlled to maintain a proper output purity. The PLC takes inputs from various pressure sensors, flow transmitters, conductivity transmitters and other sensors and provides output signals to many solenoids, valve operators and electric pumps. The control cabinet houses all of the operator switches and push buttons along with the contactors and PLC.

The unit was tested as can be seen in the video by performing the "diagnostic self test" which operates various valves and features that could be operated without providing water to the unit. The PLC, controls and valve operators worked well . The unit has only 46 hours of run time and is in good condition. The manual is very comprehensive and explains all piping and connections that are needed for each situation. Most of the accessories are included exact the large bladder storage tanks, but any tank system could be used.