| Condition Desc. | unused |

| Manufacturer | Does Not Apply |

| Model | Does Not Apply |

| Weight | 1.0000 |

This is a truck freight item which will require us to get a shipping quote. You can complete the checkout and provide payment information but you will not be charged until you agree to the freight charges. We will contact you with the freight quote. If you are providing your own shipping contact us.

Mfg: Does Not Apply

Mdl: Does Not Apply

Quantity: 1

Inventory #: 4013

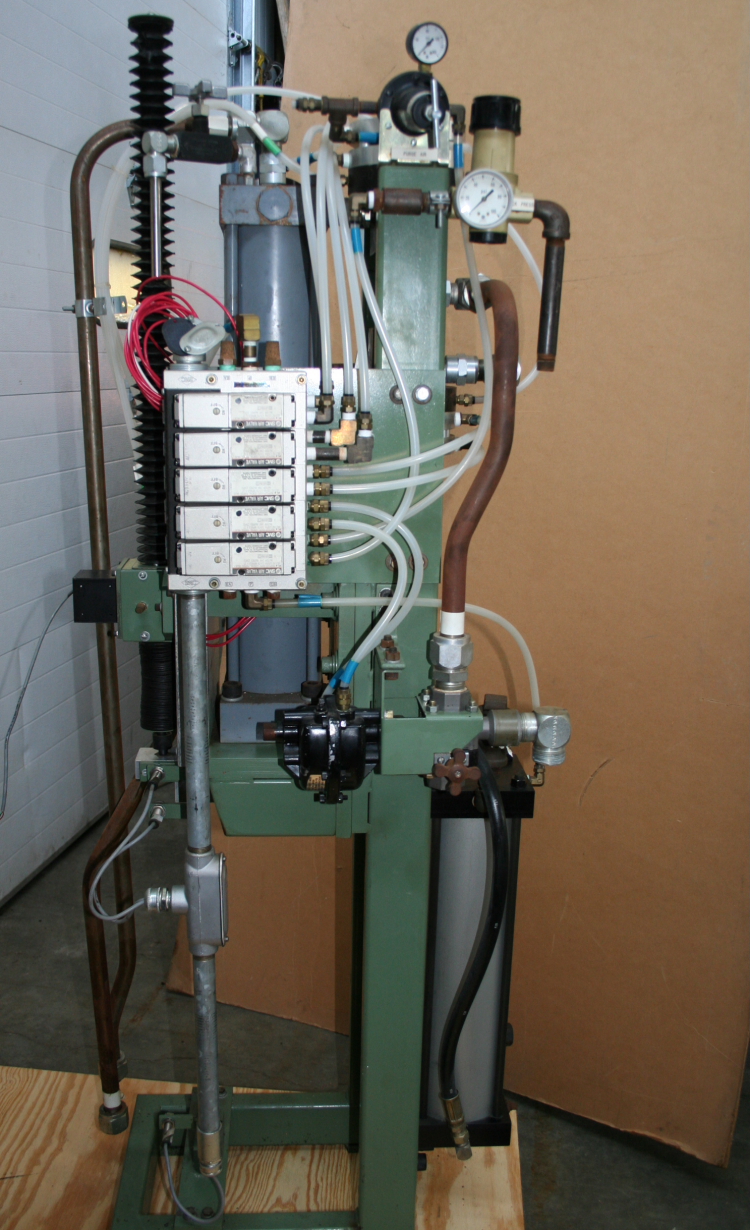

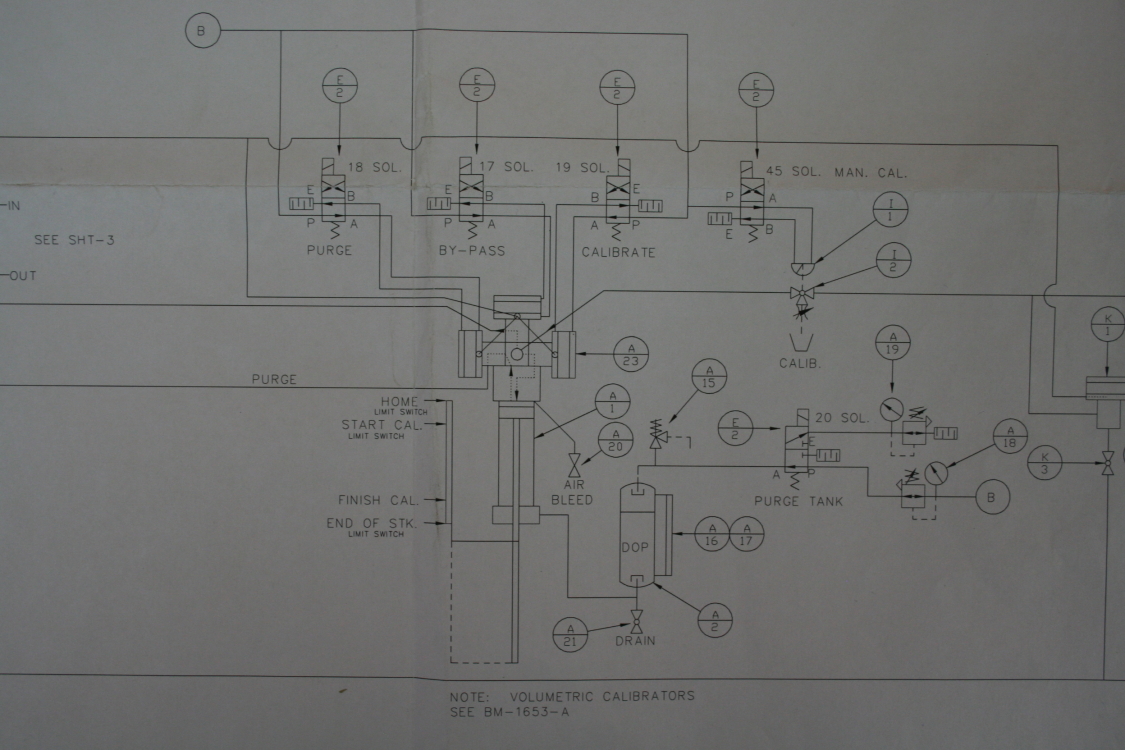

This volumetric calibration system accurately provides a known volume of fluid that can be used to calibrate flow meters in process systems. This calibrator was originally installed on a highly accurate four-component reaction injection molding machine. Normally, each chemical component passed through flow meters that monitored the flow rate. Every so often the flow was diverted into these calibrators which would create a timed stroke shot that could be compared to the flow meters' readings.

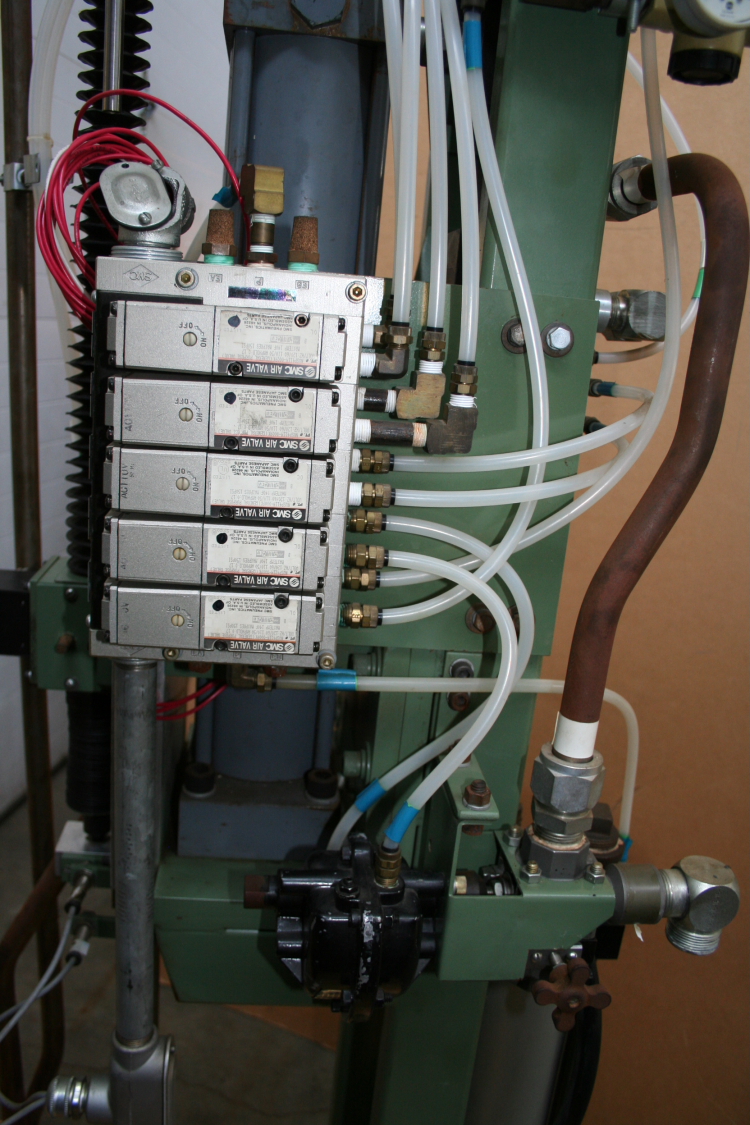

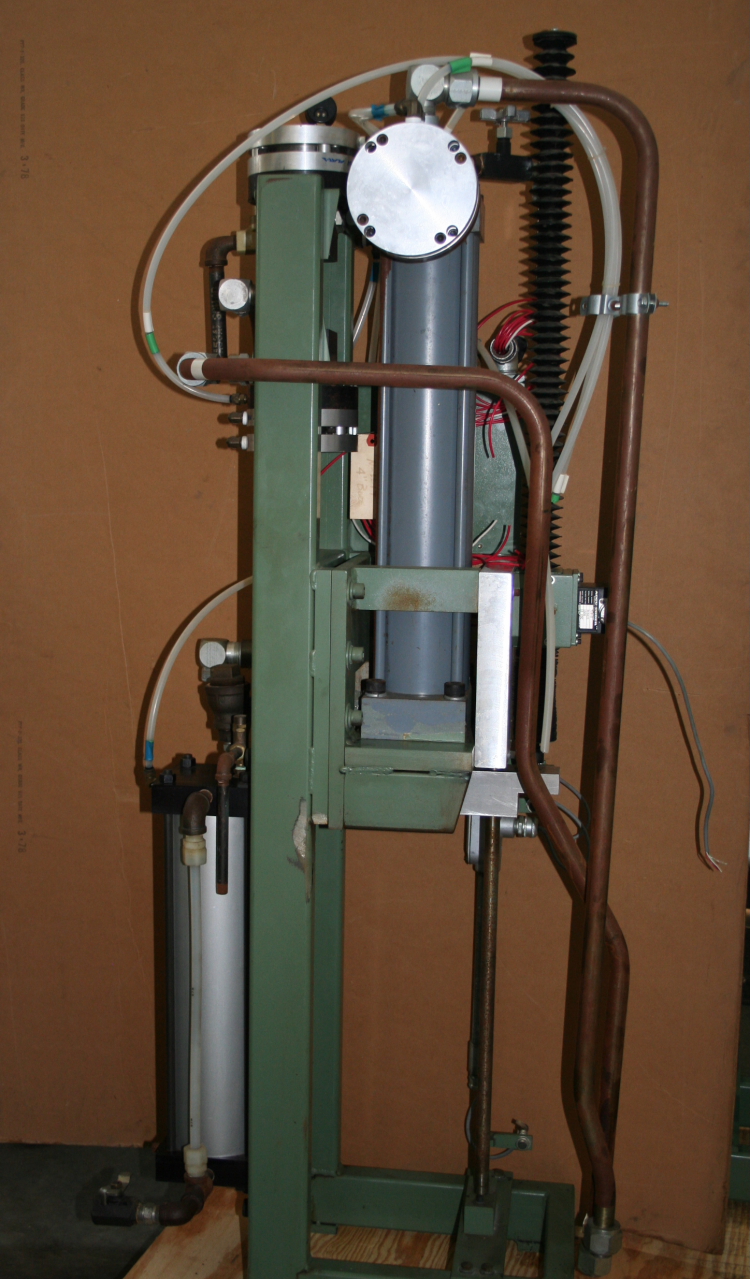

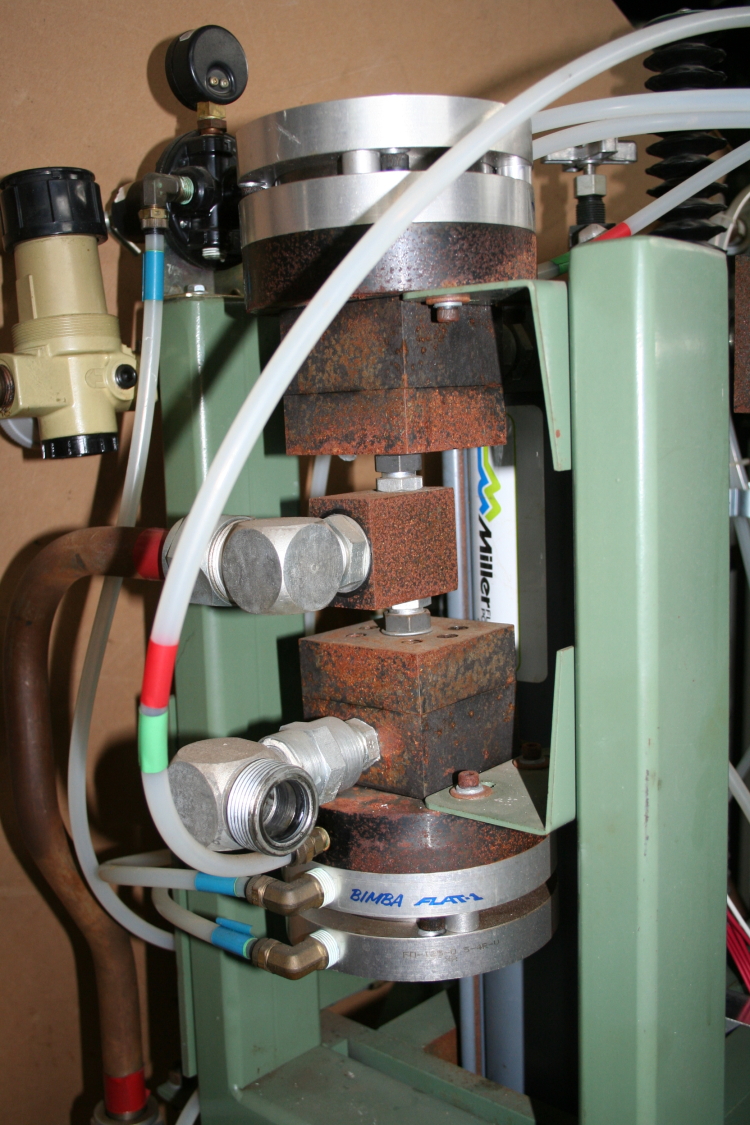

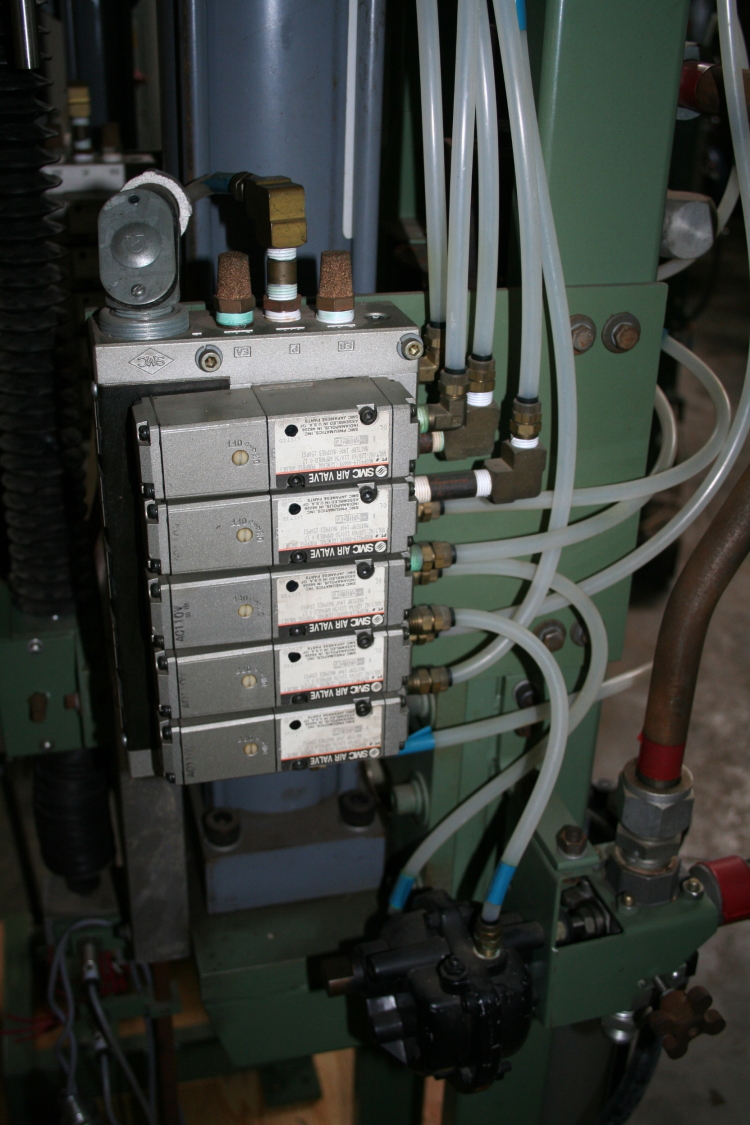

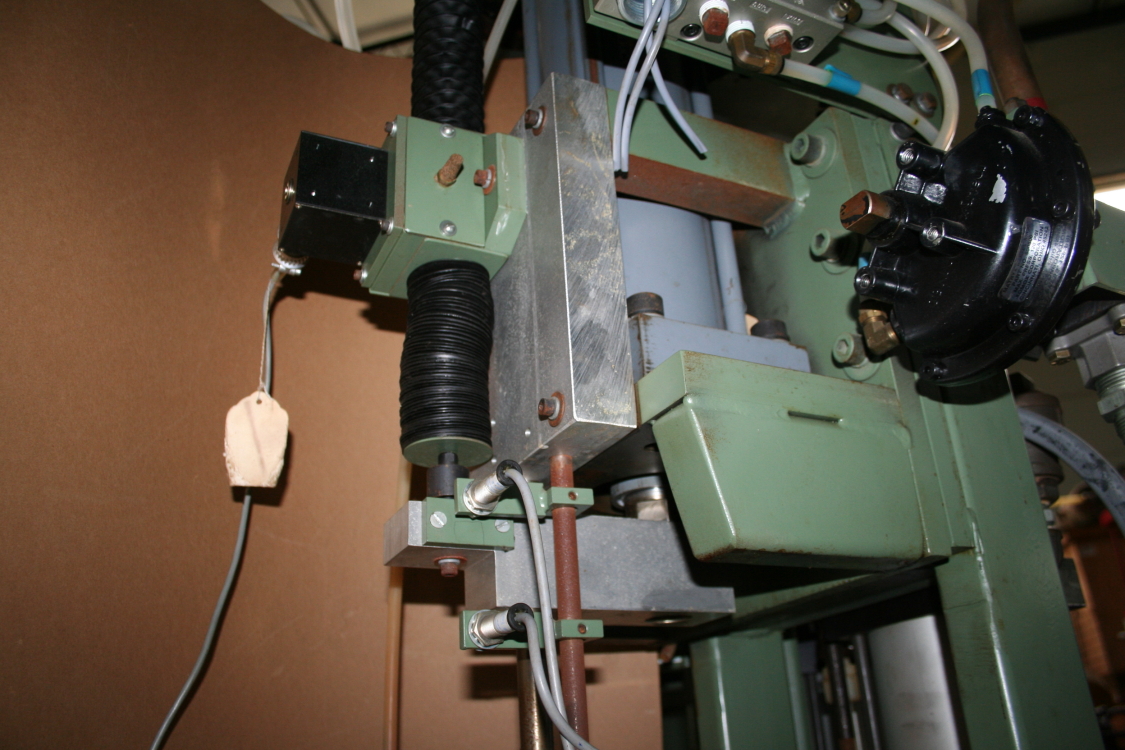

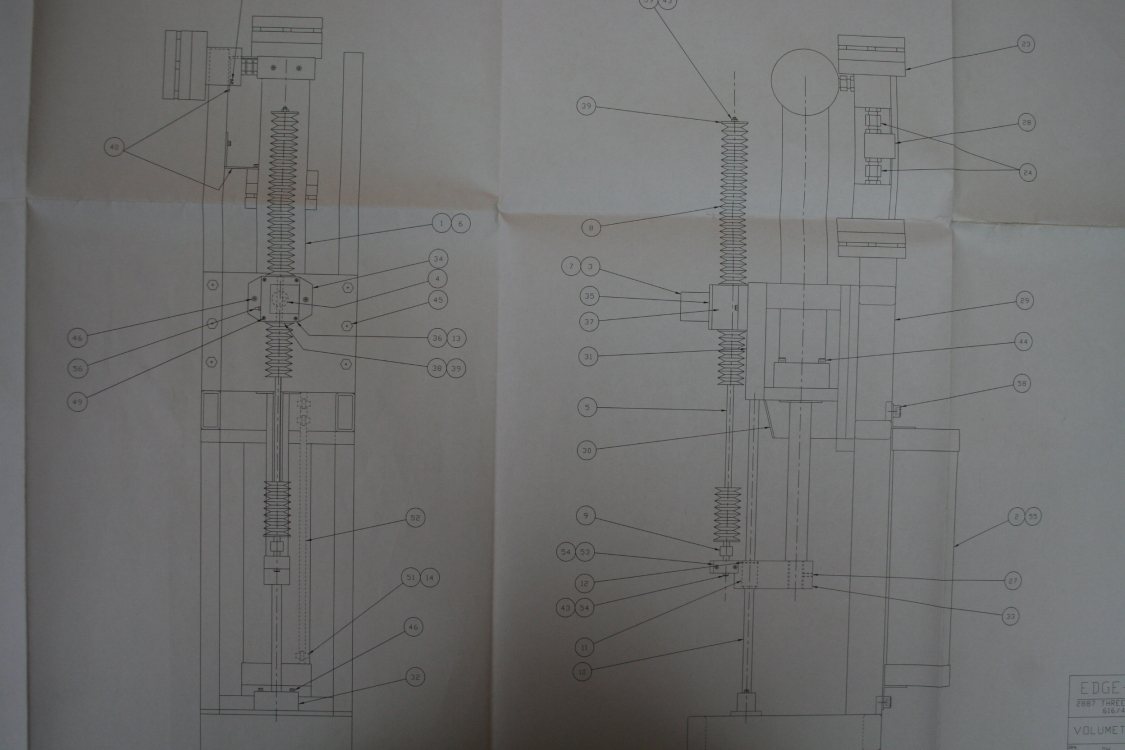

The system consists of a 4 x 20 inch hydraulic cylinder, proximity switches, rotary encoder, pneumatic solenoid valves, high-pressure control valves, and purge tank. The high-pressure control valves are pilot air-operated hydraulic valves. These high-pressure control valves direct the process fluid with inputs from the pneumatic solenoid valves. Originally, this calibrator was permanently installed on the RIM machine, but it would only be activated to check the accuracy of the flow meters. This meant there were a number of valves installed to re-direct the flow. Some of these valves may not be necessary for all applications.

Once activated, the calibrator cylinder would begin filling and the piston would extend downward. The moving piston triggers limit switches along with operating an encoder that slides on a rack gear. There are three proximity switches, home, start calibration, and end of the stroke. The placement of the start and finish limit switches, the position, and the diameter of the piston and stroke speed all determine the flow rate. After the stroke is completed, the purge tank is used to reset the calibration cylinder using a barrier fluid which forces the piston home.

To be fully operational the electrical components of this system would need to be controlled by a PLC and there would be the obvious plumbing or re-routing of fluid and pneumatic lines into your system. We do not know the exact accuracy of this system, but we do know the flow meters it was checking were Flowdata HP series meters that have a typical accuracy of 0.5%. This unit was built and installed but never put into production. We also have smaller sized units that have a rating of 10 lb/min.