| Condition Desc. | used-very good |

| Manufacturer | Rite-size Machinery Entwistle |

| Volts | 460 |

| Model | RS-60 |

| Serial # | 2005 |

| Weight | 8000 |

| Phase | 3 |

This is a truck freight item which will require us to get a shipping quote. You can complete the checkout and provide payment information but you will not be charged until you agree to the freight charges. We will contact you with the freight quote. If you are providing your own shipping contact us.

Mfg: Rite-size Machinery Entwistle

Mdl: RS-60

Quantity: 1

Inventory #: 9461

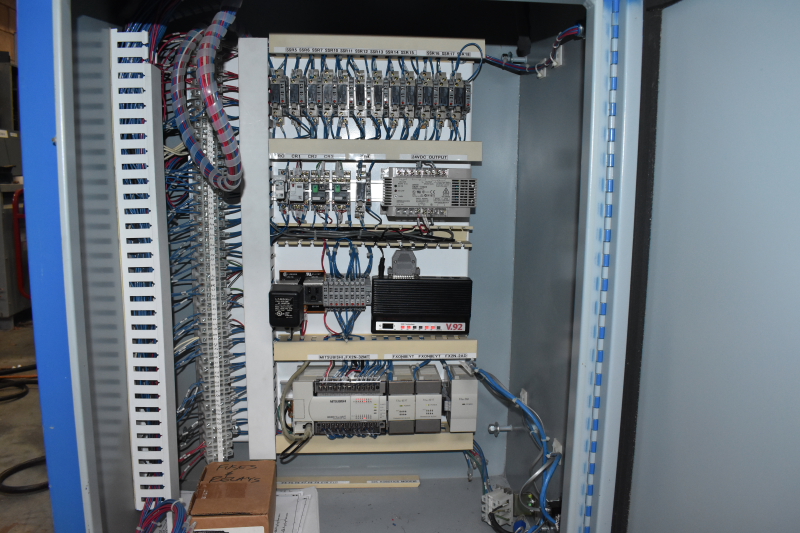

This is a 60" Ritesize box making machine in very good operating condition. Ritesize machines are used to make medium sized runs of packing cartons for carton manufacturers or manufacturing companies looking to reduce inventories of multiple carton sizes. This 60" wide electronic model can produce different sized cartons with ultra quick change-over times due to the computerized control system. Box sizes are entered on the HMI and the creasing dies automatically are positioned. Cardboard sheets up to 60" wide are feed into the machine and a finished blank is slit, scored and creased in one pass.

These Rite-size machines are heavy duty American made workhorses that have lasted decades. The overall construction is predominantly welded structural steel which creates a very rigid frame. The feed rolls and creasing bar/slotter are powered with hydraulics for maximum power and longevity. The slotter blades are heavy duty 5/16" wide sawtooth steel design versus a razor blade design of other machines. Many of the parts such as air cylinders, hydraulic cylinders, hydraulic motors, electrical components and pneumatic components are all off the shelf parts that could be obtained easily.

There is some indication the machine was lightly used but not much. We powered up the unit and tested its operation and it worked well as can be seen in the video link below. Full manual and complete set of prints included along with a box of new spare parts such as encoders, gears, rubber feed wheels and electrical parts.

Box sizes

Because the overall capabilities of the machine are based on the relationship between the three dimensions to each other the closest one can come to answering the question, "how big of a box can I make" is to use a formula to see if the sum of the dephth and width of the box are less than the 60". There is no limitation to the board blank length but in practice the length would be limited to the space available beyond the end of the runoff table.

So by using a 28L x 24W x 30D box as an example... The blank width = 24 + 30 + 1 3/8 (crease allowance) = 55 3/8" blank width. This blank width is under 60" so you could make this box on this machine and the 28" length could even be larger since it is not an influence on the width.